Hyperion Materials & Technologies has more than two decades of experience developing cemented carbide wear parts and solutions that meet the demanding requirements of the automotive industry. We partner with our customers to improve performance and develop solutions for their automotive wear part applications.

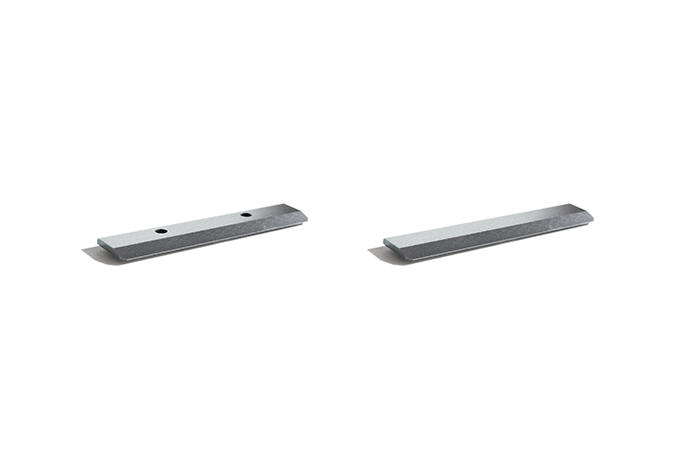

The automotive industry depends on high-performance cutting implements for such operations as milling the grooves in v-belts and cutting the camber on the side of the belts. Minimizing the total cost of ownership (TCO) for automotive industry manufacturers has been a primary directive for more than a century and remains so today. Automotive wear parts such as cutting tools and knives deliver high performance when made from super-hard materials for the most effective cutting edges and maximum utility.

Hyperion Materials & Technologies has certification to IATF 16949:2016 (Barcelona, Spain location) for manufacturing cemented carbide components from sintered to fully finished condition. All laboratory personnel are skilled metrologists with decades experience in gage inspection and all inspection equipment and master blocks have precision traceable to the National Institute of Standards and Technology (NIST).

Precision Solutions is an ISO 9001:2015 certified organization and has a temperature controlled gage laboratory onsite compliant to the National Institute of Standards and Technology (NIST) to meet your inspection standards. We developed a Quality Management System which guarantees that every workpiece machined meets or exceeds the required tolerances and the customers expectation.

Precision Solutions strives to invest in the most effective inspection equipment needed in today’s precision manufacturing world. We intend to remain on the forefront of the newest cutting edge technology in the gage inspection world.

Crafts Technology achieved ISO 9001:2008 Compliance in 2010. The site has adopted a quality management system based on this international standard. The standard is used by several companies to assess their ability to meet customer, statutory and regulatory requirements applicable to its products, along with the company’s own requirements.

Crafts Technology completes yearly audits of our system, with customer issued audits taking place every 3 years.

Precision Solutions manufactures many carbide products and components in the automotive market including wear plates, needles, shafts, valves and pins. The applications we support our customers with include injector components, high pressure pumps, valve trains and turbochargers.

Our customers chose Precision Solutions because of the high wear and abrasion resistance our products deliver. The reliability of our cemented carbide directly supports system efficiency.

Material selection plays a key role for the reliability and efficiency of fuel injections to handle such pressure, high temperature, corrosion, or a combination of these conditions.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.