A Carbide Tool Company

With decades of experience, we develop cutting-edge tools for metal packaging, slitting, sawing, and various industrial applications. Our expertise, state-of-the-art technology, and commitment to precision make us a vital part of the Precision Solutions by Hyperion family, driving innovation in industries where accuracy and performance matter most.

We are a Wood Dale, Illinois-based company that specializes in grinding and EDM finishing of carbide and ceramic components. We also develop tools for metal packaging, slitting, sawing and a wide variety of general industrial applications. Damen Carbide’s core competencies and manufacturing capacity, backed by with decades of manufacturing expertise, is a significant addition to the Precision Solutions by Hyperion.

Damen Carbide is dedicated to enhace its Quality Management System (QMS). This includes emphasizing the importance of meeting customer, regulatory, and legal standards, establishing quality objectives, and ensuring that the necessary resources are available to maintain high standards of performance.

Damen Carbide Tool prioritizes identifying and addressing both current and future customer needs. By thoroughly understanding customer requirements and translating them into internal procedures, the company ensures customer satisfaction and strives to exceed expectations.

Damen Carbide is committed to consistently meeting customer needs. With a focus on continuous improvement, the company emphasizes that delivering high-quality products and services is the responsibility of every employee. This quality policy is regularly reviewed to ensure its ongoing effectiveness within the organization.

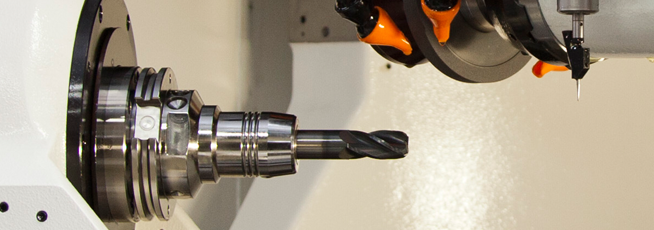

At Damen Carbide Tool, we engineer and manufacture a wide range of precision tools, including End Mills, Form Tools, Saws, and Knives. Our advanced grinding machines allow us to produce and re-sharpen tools with superior accuracy and quality. We specialize in reverse engineering and offer custom solutions to cut through all materials. Our tools range in size, with End Mills and Form Tools reaching diameters of 6.35mm to 102mm, and Saws and Knives from 12mm to 300mm in diameter. With extensive customization options, we deliver tools tailored to exact specifications, ensuring optimal performance for every application.

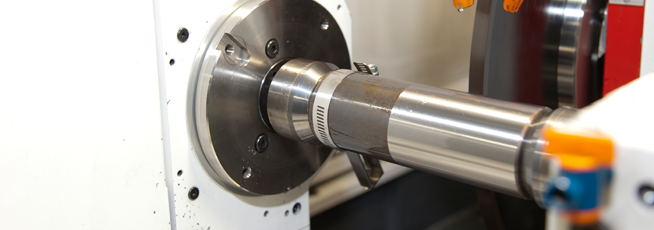

Damen Carbide Tool excels in O.D. (Outside Diameter) grinding, utilizing advanced technology to handle complex profiles, angles, and taper grinding with exceptional precision. Our grinding capabilities include in-process gauging, external form and thread grinding, and out-of-round grinding. We can accommodate diameters up to 18 inches and lengths up to 63 inches, all within a tolerance of +/- .00005 inches. Our O.D. grinding services are designed to deliver consistent, high-precision results for even the most demanding industrial requirements.

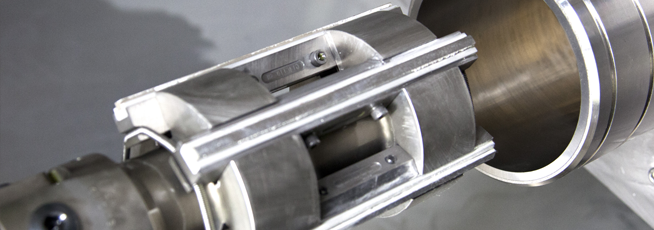

Our I.D. (Internal Diameter) grinding services utilize the latest generation of internal cylindrical grinding machines, ensuring precision and efficiency. We specialize in complex profiles, angles, radii, and taper grinding, offering C-axis form and thread grinding with in-process gauging. With internal grinding capabilities for diameters up to 15 inches and lengths up to 12 inches, and a tolerance of +/- .00005 inches, Damen Carbide Tool is equipped to deliver superior accuracy and consistency for your most critical internal grinding needs.

Damen Carbide Tool provides precise surface grinding solutions, featuring specialized fixtures and indexing for detailed angle grinding. Our surface grinding capabilities accommodate parts up to 12 inches by 24 inches, with tolerances as tight as +/-.0001 inches. Whether you require flatness, smooth finishes, or custom surface geometries, our surface grinding services ensure high-quality finishes and dimensional accuracy.

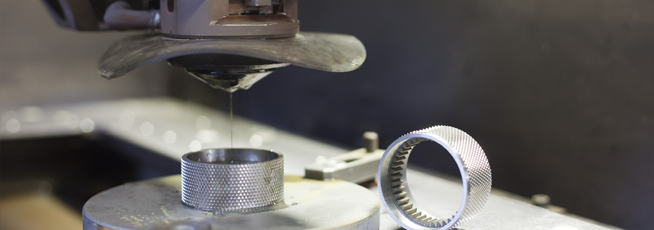

Our EDM (Electrical Discharge Machining) services include both Wire EDM and Sinker EDM, specializing in the creation of complex taper shapes with high precision. Powered by ESPRIT Software for NC code generation, we achieve superior accuracy with tolerances up to +/-.0001 inches and surface finishes as fine as 4 microns. Our EDM capabilities handle components up to 12 inches in height, ensuring precise machining of intricate parts where conventional methods fall short.

Damen Carbide Tool offers high-precision honing services for both vertical and horizontal applications, backed by advanced gauging systems for unmatched accuracy. Our vertical honing capabilities accommodate internal diameters from .75 inches to 9 inches, with lengths up to 60 inches and tolerances of +/- .0005 inches. Our horizontal honing services handle internal diameters from .125 inches to 3 inches, with lengths up to 8 inches and tolerances of +/- .0001 inches. These capabilities ensure we meet exacting standards for bore finishing, delivering consistent and reliable results for your most demanding applications.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.