Precision Solutions develops high performing hard and super-hard materials used in drilling, completion and flow control applications. The flow components and tooling manufactured by Precision Solutions are used in a wide variety of challenging oil and gas operations, from pipelines to gas and liquid measurement. The measuring of the flow of liquids involved in oil operations on and offshore demand quality flow measurement performance. Our customers expect the highest expectations will be met in regards to performance and quality with the parts we manufacturer.

Hard and super-hard materials are chosen based on the application and therefore, different grades of carbides and ceramics have better characteristics for flow metering applications than others. Many companies use nickel carbides, which are preferred in corrosive environments, such as water and water soluble pollutants. Carbides are known to improve durability and minimize maintenance over time. Other customers prefer ceramics because of the low thermal conductivity and heat resistance properties. Our engineers are on stand-by to help you find the right material for your exact needs.

Surface finish and wear characteristics are of most importance to our Energy customers. This is because of contact surfaces (surface finishes) and increasing component life (wear characteristics). Surface finishes have a large impact on the performance and durability of a part. Many components developed for this segment require surface finishes of 4RA (.1016 micron) or better, tolerances as tight as .000010″ (.000254mm) and highly complex geometries. We strive to be an extension of your engineering team to help you meet the demanding needs of these parts.

Our team has decades of experience in drilling, well completion, and hydrocarbon production. PDC bits, MWD/LWD components, drill nozzles, and directional drilling components allow our partners to create their wells. Finishing inserts used to clear debris from the well as well as Frack pump valves and valve seats allow our partners to prepare their wells for production. Flow cages, sleeves, and metering valves allow our partners to extract hydrocarbons safely and efficiently. From drilling to production, we provide value.

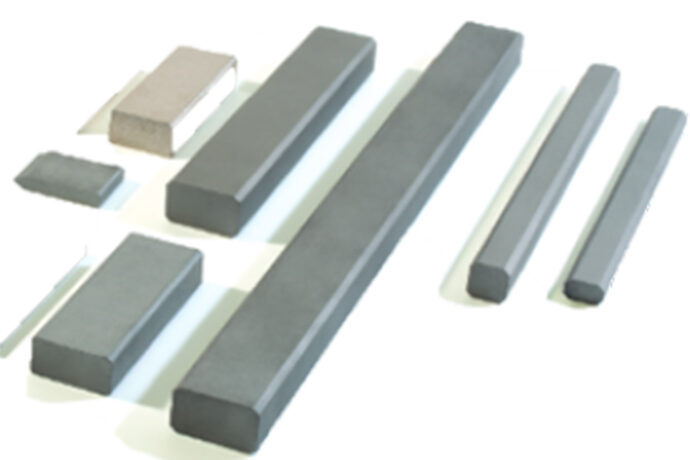

Hyperion Materials & Technologies manufacturers high quality cemented carbide inserts used for stabilizer pads. Specific high-performance carbide grades are developed for the stabilizers downhole. Coatings are also available for your specific applications. Our wide-range of Standard Stabilizer Blanks can be manufactured in PCD or carbide. We will assist you in the best suited material to solve your needs.

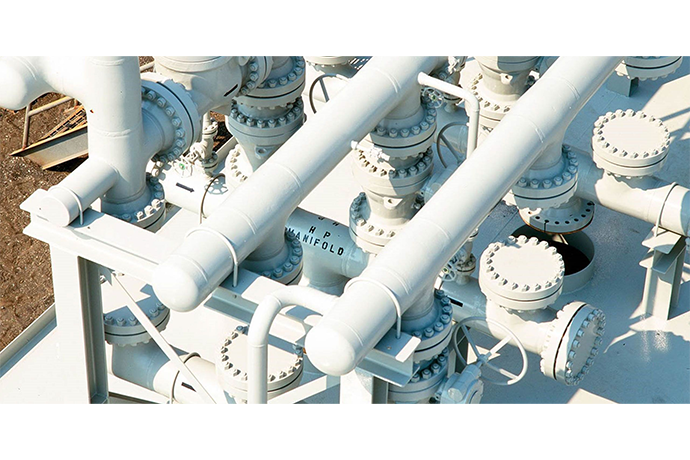

Experts in highly-engineered components, Precision Solutions by Hyperion develops valves, valve seats, and flow control needles for hydraulic fracturing applications. These components exhibit extreme wear-resistance and extreme corrosion resistance which translates to savings for natural gas producers and lower cost energy bills for the average consumer.

Sourcing complete assemblies from Hyperion gives our customers freedom and flexibility in the face of unpredictable market demand. Hyperion manufactures cemented carbide finished valve components with final tolerances exact enough that they can be directly assembled or used to make sub-assemblies for flow control valves. Assemblies are supplied as finished cemented tungsten carbide parts joined to steel or super alloys using a variety of joining methods, such as interference fit, heat shrink fit, brazing and epoxy.

The components include cages, sleeves, seats, points, rings, and discs for different design valves.

The energy industry faces significant challenges due to the harsh conditions of subsea drilling. The use of reliable, high-performance materials is essential to mitigate these challenges and ensure the safety and reliability of subsea drilling operations.

Read more about carbide grade CR9C and how it delivered the toughness and the corrosion and cavitation resistance the energy industry needed.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.