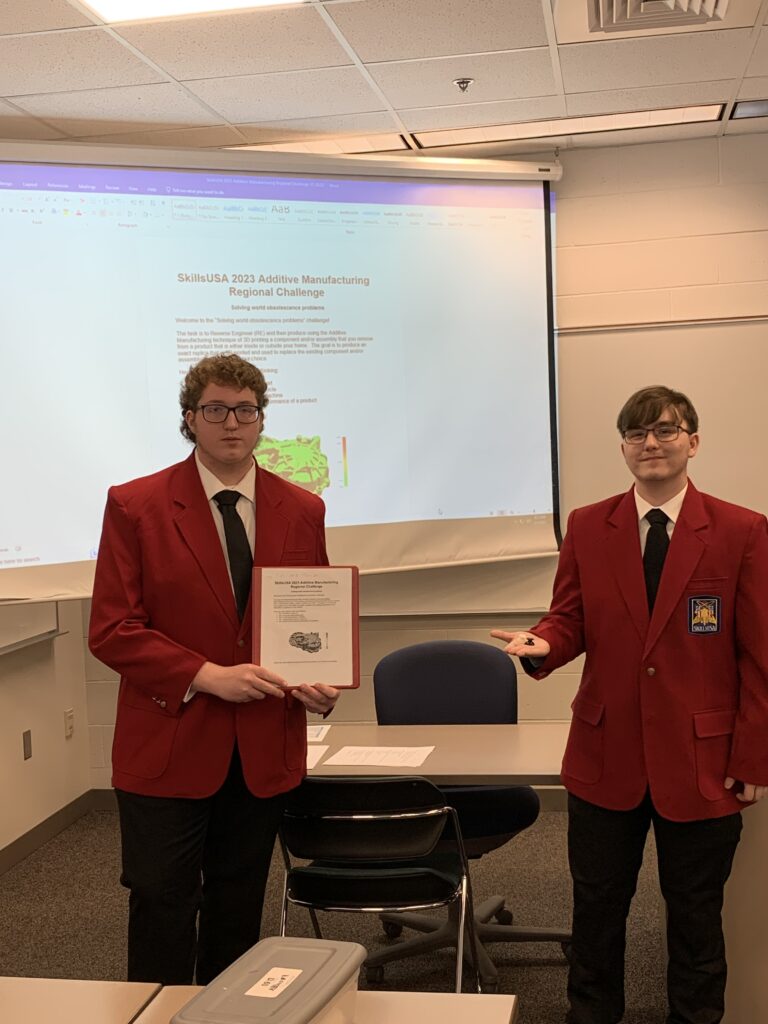

GLE-Precision Participates in Additive Manufacturing Judging Competition

On Friday, March 3rd, Delta College hosted the “Skills USA 2023 Additive Manufacturing Regional Challenge”. The challenge required high school students to complete a variety of tasks focused around additive manufacturing. Ultimately, the purpose of this event was to evaluate each contestant’s preparation for employment and to recognize these outstanding students for excellence and professionalism in the field of Additive Manufacturing. Students were tasked with providing engineering notebooks, discussing how they reverse-engineered a product, presenting designs to judges, answering questions, highlighting the functionality of the 3D printed components, and providing resumes to the judges.

More on Additive Manufacturing

In simple terms, additive manufacturing is 3D printing. This practice allows researchers to create physical, three-dimensional objects from a computer design file. Additive manufacturing embraces a wide range of materials and derivative process building parts suitable for end-use service. The unlimited design freedom enabled by additive manufacturing allows the creation of shapes and the integration of features and function that previously required subassemblies. Printing in three dimensions plays a role in nearly every industry. From teaching creativity in education to designing surgical guides in difficult medical procedures to cost savings in manufacturing, 3D printing demands of its practitioners’ literacy in many areas.

Scope of the Competition

Students were evaluated based on their performance in the following areas:

- Knowledge Performance

- Skill Performance

- Academic Skills (Math, Science, Language Arts)

- Connections to National Standards

Regarding the “Knowledge Performance” section, all individuals participated in taking the Additive Manufacturing Fundamentals Certification Exam. The certification in Additive Manufacturing Fundamentals is the first and only certification validating an individual’s knowledge of industry standard concepts in additive manufacturing. A passing score of 70 percent or higher is needed for the competitor to earn the Additive Manufacturing Fundamentals Certification.

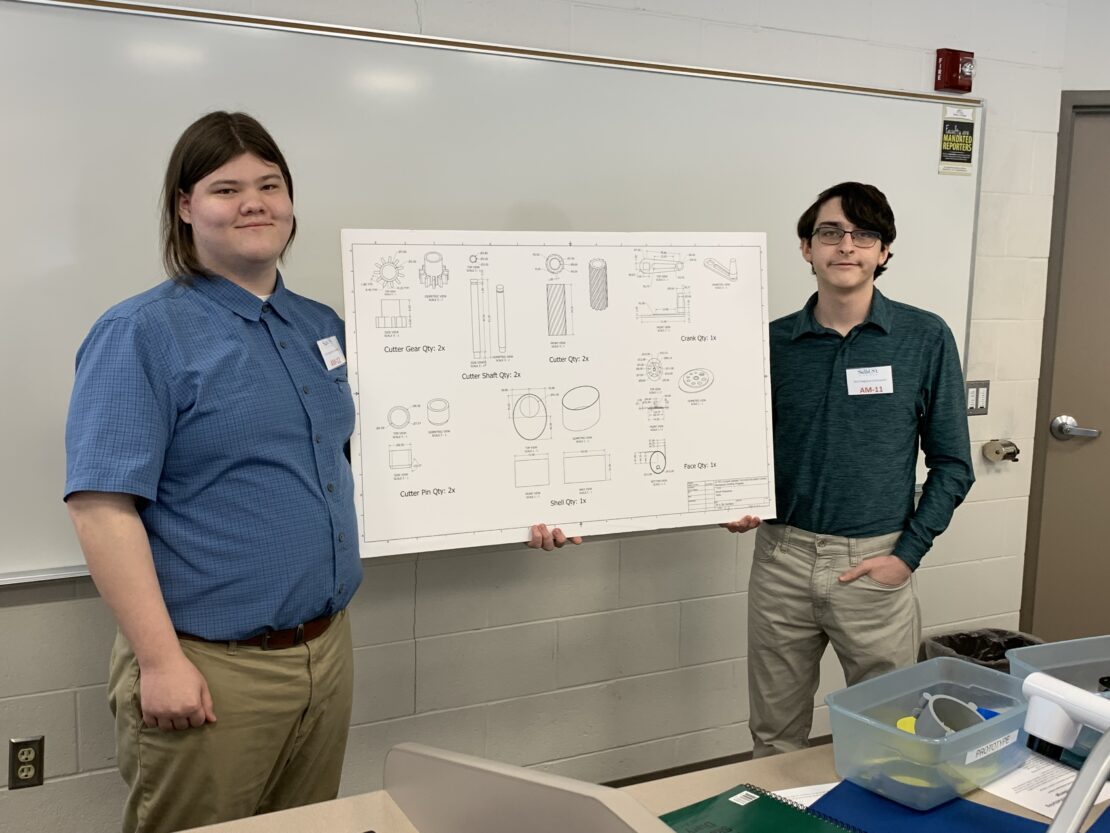

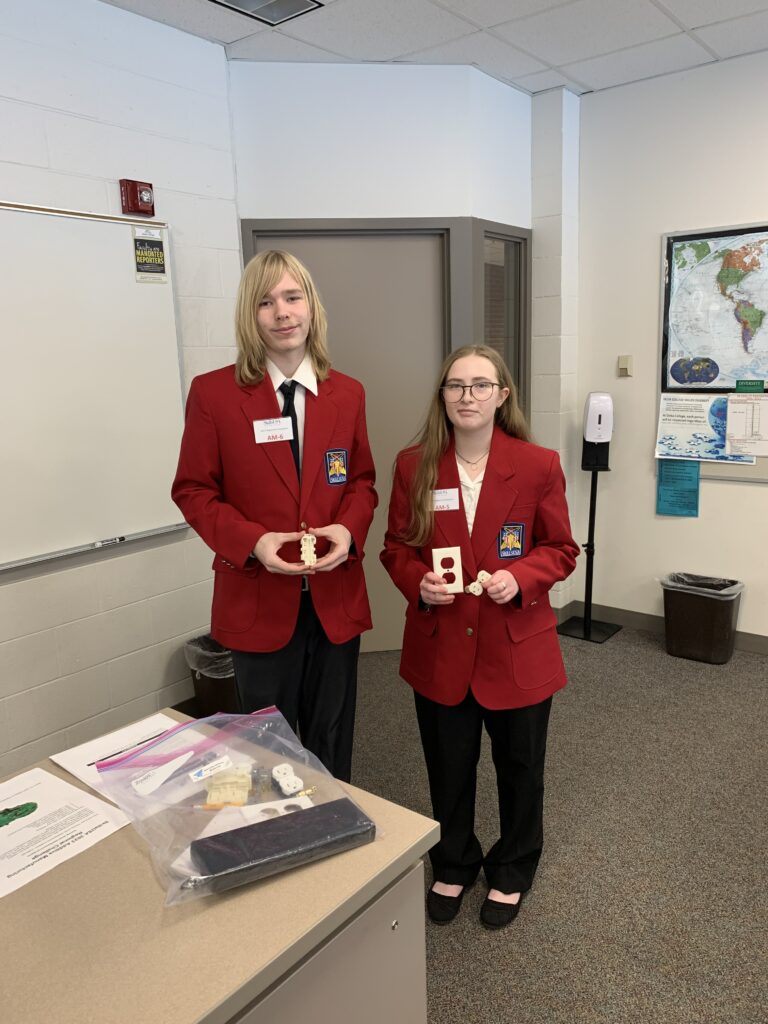

The competition was a team-oriented event, and the teams were comprised of two competitors from the same school in the same division. The students put their skills to the test by their 3D design that demonstrated a thoughtful design for additive manufacturing and solved a given problem under given constraints. The competition focused on real-world challenges that tested the teams’ understanding of physical, functional, and performance characteristics or specifications that uniquely identify a component or device and determine its interchangeability in a system. The teams’ final designs demonstrated their ability to design for integration into an existing process and adapt to an existing design/interface.

Fit, Form, and Function

This is what the committee was looking for… fit, form, and function. Throughout the whole day, students were evaluated and did a phenomenal job utilizing the Engineering Design Process. Other questions these scholars were able to answer through their skills were, “does it perform the function in the manner it was designed to do?” and “did the students design the part with additive manufacturing in mind?”.

From a presentation standpoint, the students’ impressed by clearly describing their understanding of the problems at hand, their professionalism, and their practical evaluation.

Meet the Teams

Conclusion

The skills that were on display at the “Skills USA 2023 Additive Manufacturing Regional Challenge” were beyond impressive. Many students from different schools showcased their incredible talents in front of a committee evaluating them on their preparation for employment and recognizing their outstanding excellence and professionalism in the field of Additive Manufacturing. The students did not disappoint!

Thank you to Aaron Kipfmiller, Oliver Johnson, and Delta College for having us play a part in this outstanding event!